PETamentor is an open-source project that enables 3D printing enthusiasts to turn waste PET bottles into usable filament. This PET bottle filament machine has gained attention in the maker community as a DIY filament solution for eco-conscious hobbyists. By utilizing a simple setup of a motor, heated nozzle, and spool mechanism, PETamentor offers a low-cost way to create filament from plastic bottles.

This article explores user experiences, forum feedback, and expert reviews of PETamentor. While the overall sentiment is positive – highlighting cost savings and sustainability – some users report technical challenges. In the final section, we’ll cover critical feedback and potential improvements.

What is PETamentor and How Does It Work?

PETamentor is a DIY filament extruder designed to transform PET bottles into printable 3D filament. The process involves:

- Cutting the bottle into a continuous strip

- Feeding the strip into a heated nozzle

- Melting and shaping the strip into a filament

- Winding the filament onto a spool

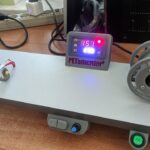

Unlike other filament recyclers, PETamentor is designed for simplicity, using common components such as a W1209 thermostat, a DC motor driver, and an extruder hot-end. Its goal is to allow makers with minimal technical skills to DIY their own filament.

User Experiences: Successes and Challenges

Browsing through forum discussions and reviews, many users have successfully built and tested PETamentor. Reported positive aspects include:

Positive Feedback:

- Cost-effective recycling of PET waste

- Simple assembly with clear instructions

- Produces printable filament with proper calibration

Challenges:

- Fine-tuning temperature and speed is crucial for consistent filament quality

- Filament requires thorough drying before printing to avoid moisture-related defects

- Manual cutting of PET strips can be time-consuming

Overall, PETamentor is highly regarded among 3D printing enthusiasts who enjoy experimenting with DIY filament. The community offers extensive support and tips to help improve output quality.

Expert Reviews and Media Coverage

PETamentor has been featured on several tech websites. For example, Hackaday praised its affordability and open-source nature, highlighting a reliable extrusion process along with minor suggestions for improvement.

Other sources, such as Instructables and various maker forums, discuss the project as a viable, eco-friendly solution for producing PET bottle filament. These articles often emphasize the educational value and sustainability benefits of the DIY approach.

Challenges and Areas for Improvement

While PETamentor is a promising project, users have noted a few areas for improvement:

- Filament consistency: Achieving a uniform diameter requires careful adjustment of extrusion settings.

- Throughput: Producing a full spool demands many bottles, as each bottle yields only a small amount of filament.

- Printability: Drying the filament thoroughly is essential to prevent printing defects caused by moisture.

Future iterations, like PETamentor2, aim to address these challenges by integrating an automatic bottle cutter and refining the extrusion control. Such improvements could help make the process more efficient and the filament more reliable for everyday 3D printing.

Conclusion

PETamentor is an innovative solution for DIY filament recycling. It offers 3D printing enthusiasts a sustainable, cost-effective method to repurpose PET waste into usable printing material. Although it requires careful calibration and patience, the potential benefits make it a rewarding project for makers.

As the project evolves, further improvements in automation and filament consistency could enhance its appeal. For those passionate about 3D printing and sustainable making, PETamentor represents a unique opportunity to turn everyday waste into valuable resources.

Do you have experience with PETamentor? Share your thoughts in the comments below!

Leave a Reply